28 pieces of equipment, including

Factory

Opening

In the heart of Mangystau — modern technology and rich heritage

In the industrial zone of Aktau, on the site of the legendary AKMO-88 plant, Acton Flow LLP now operates as one of the region’s leading manufacturers of pipeline fittings and oilfield equipment.

We take pride in our history and continue it with a new standard of quality. By upholding the finest traditions of mechanical engineering, Acton Flow combines the experience of past generations with cutting-edge technologies.

Our production capacities include:

-

-

16 high-precision CNC machines

-

2 powerful 4-axis horizontal machining centers, each weighing 25 tons

We take pride in our history and continue it with a new standard of quality. By upholding the finest traditions of mechanical engineering, Acton Flow combines the experience of past generations with cutting-edge technologies.

Industrial equipment manufacturing

Industrial Equipment Production

Pipeline Fittings

Gate valves, ball valves, check valves for high-pressure and aggressive media systems

Oil & Gas Equipment

Reliable solutions for the oil and gas industry

Industrial Pumps

Pumping viscous and abrasive fluids, tailored to client requirements

Overview of core equipment

Brief Overview of Main Equipment

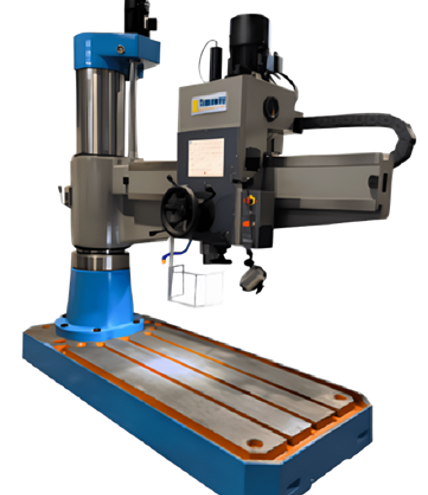

- Max. turning diameter over bed: 630 mm

- Max. turning diameter over carriage: 420 mm

- Weight: 4,300 kg

- Dimensions: 4200×2050×1880 mm

- Quantity: 6 units

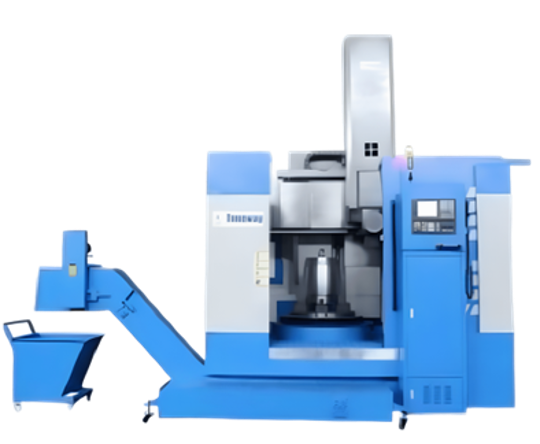

- Table diameter: 1010 mm

- Swing over cross slide: 1250 mm

- Weight: 2,000 kg

- Dimensions: 5200×3250×4380 mm

- Quantity: 4 units

- Max. turning diameter over bed: 800 mm

- Max. turning diameter over carriage: 450 mm

- Weight: 4,300 kg

- Dimensions: 4400×2150×2580 mm

- Quantity: 2 units

- Max. turning diameter over bed: 630 mm

- Max. turning diameter over carriage: 420 mm

- Weight: 4,300 kg

- Dimensions: 4200×2050×1880 mm

- Quantity: 6 units

- Table size: 1000×1000 mm

- Axes: 4

- Weight: 23,000 kg

- Dimensions: 8000×5200×3800 mm

- Quantity: 2 units

Description of the production process

Production Process Overview

Equipped with modern machinery and strict quality control at every stage

Machining of the Wedge Gate Valve Stem

Raw material arrives as semi-finished blanks—hollow metal discs Ø15–50 mm. Processing stages:

Cutting blanks to the required length

Turning external/internal threads on a lathe per the drawing

Hardening in a furnace to increase strength and wear resistance

Final machining to remove deformations and achieve required tolerances

Machining of the Gate Valve Body and Bonnet

- Investment casting (LVM) for high precision and excellent surface finish

- Minimal secondary machining due to accurate castings

-

Turning operations:

- Up to Ø350 mm — horizontal lathe

- Above Ø350 mm — vertical lathe

- Drilling connection holes for pipeline integration

Hardfacing and Lapping of the Seat Surface

- After turning, the body is sent to the hardfacing station

- Application of wear-resistant chrome-nickel alloy to the seat

- Finish turning to achieve precise geometry and smoothness

- Final lapping of the seat and wedge on specialized equipment

- Ensures class “A” sealing per industry standards

Assembly, Testing, and Preparation for Shipment

- Assembly: all components (body, wedge, bushings, seals, etc.) are assembled into the finished valve

- Testing: hydraulic and pneumatic tests for strength and leak tightness

- Painting & Packaging: anti-corrosion coating, labeling, and preparation for transport

- Quality control at every stage ensures reliability and longevity

Advantages

Advantages

- Equipment with certificates and proven origin

- Official contracts and transparent documentation

- Reputation you can trust

- No unnecessary subcontractors

- Saves time and resources

- Selection → Supply → Installation → Documentation

- Fast selection and production ramp-up

- Standard items always in stock

- In-house production = independence

Advantages in comparison with analogues

Advantages Compared to Competitors

- Body: carbon, alloyed and stainless steels

- Seals: PTFE, graphite, chemically resistant rubbers

- Incoming inspection: chemical composition analysis, UT, MT

- CNC machines with 0.01 mm accuracy

- Lapping of working surfaces

- Repeatability of geometry and dimensions

- Assembly in a clean-room environment

- Hydraulic tests for strength and tightness

- Application of serial numbers and passport data

- Preparation of passports, certificates, and test reports